X-Ray Component Counter Technology in PCBA Assembly

X-Ray Component Counter technology is an essential tool in modern Printed Circuit Board Assembly (PCBA) factories, moving component inventory management from manual estimates to high-precision automation. This non-contact inspection system utilizes low-dose X-rays to quickly and accurately count the number of electronic components sealed within their tape-and-reel packaging.

The Operational Principle

The X-Ray counter operates on the principle of differential X-ray absorption. Electronic components, particularly integrated circuits (ICs), transistors, and passive devices, are constructed using materials of varying density (silicon, copper, ceramic, metals). These materials absorb X-rays differently than the surrounding packaging materials (plastic or paper tape, plastic reel).

- X-Ray Emission: A focused, low-dose X-ray beam is directed at the component reel. The beam penetrates the packaging material.

- Absorption and Attenuation: The dense component materials attenuate (absorb) more of the X-ray energy than the less-dense tape.

- Detector Array: A flat-panel detector array (similar to those used in digital radiography) captures the X-ray energy that successfully passes through the reel.

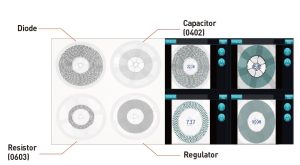

- Image Processing: The captured image shows the components as distinct, darker shadows against the lighter background of the tape. Sophisticated image recognition software and algorithms analyze the image pattern to identify each individual component pocket and count the contents.

This process provides a precise, non-destructive count of the components, usually completing the scan in a matter of seconds.

Key Applications and Benefits

The primary value of X-Ray counting is the prevention of errors and downtime in the high-speed SMT assembly line:

- Real-Time Inventory Accuracy

Manual counting is time-consuming and error-prone. The X-Ray counter provides an immediate and verifiable count, ensuring the Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) systems have accurate inventory data. This is crucial for “just-in-time” manufacturing environments.

- Feeder Setup Verification

Before an SMT Pick-and-Place machine starts a job, the operator must load component feeders. X-Ray counting is used to confirm that the reel loaded onto the feeder contains the required minimum number of components to complete the job, preventing a costly “running out of material” (ROM) stop midway through the assembly process.

- Small Component Counting

Counting ultra-small passive components (like 01005 or 0201 chip resistors/capacitors) is virtually impossible manually. The high resolution of the X-ray system makes these miniature components easily countable, ensuring accurate stock levels for the smallest, highest-volume parts.

- Traceability and Quality Control

Advanced systems can integrate the component count, part number, and reel barcode into a central database, improving traceability. If a reel is returned to the warehouse, the count is instantly updated, maintaining data integrity.

Integration into the Smart Factory

X-Ray component counters often feature automatic reel loading/unloading and robotic integration, fitting seamlessly into the Industry 4.0 vision of the smart factory. By eliminating material shortages and reducing the time spent on manual counting, this technology significantly boosts the overall Overall Equipment Effectiveness (OEE) of the SMT production line

P&C Enterprise Solutions (PCES) is a trusted OEM/ODM electronics manufacturer based in Vietnam. Our electronic components and embedded solutions have been delivered to customers across Europe, Asia, and the Middle East, supporting a wide range of industries including audio systems, GPS devices, elevators, lighting, and automation. With strong in-house capabilities in product design, hardware, firmware, and mass production, we provide fully customized solutions tailored to your specific project requirements.

P&C owns the HAWKEYE1000 X-Ray Component Counter, which is the latest generation model from the manufacturer TechValley.

Source: PCES