The Full-Function SMT Line – The Backbone of Modern Electronics

The Surface Mount Technology (SMT) line is the technological heart of modern electronics assembly. It is a highly automated, sequential process designed for the high-speed placement and soldering of miniature electronic components onto a Printed Circuit Board (PCB). For those knowledgeable in this domain, understanding the function of each station and, critically, the impact of equipment quality is paramount to achieving high yield and long-term product reliability.

Architecture of a Full-Function SMT Line

A comprehensive SMT line is not merely a collection of machines but a tightly integrated system comprising six essential stages, each connected by automated conveyors:

- Solder Paste Printing

This is arguably the most critical stage, responsible for laying the foundation of the solder joint.

- Equipment: Automatic Solder Paste Printer (Screen Printer).

- Function: Applies a precise volume of solder paste onto the PCB pads through a metal stencil using a squeegee mechanism.

- Quality Reliance: Printer alignment accuracy (X, Y, θ) and squeegee pressure control are fundamental. A poor printer leads directly to volume defects (insufficient, excessive, or offset paste), which account for the majority of reflow defects.

- Solder Paste Inspection (SPI)

The first in-line quality gate, positioned immediately after printing.

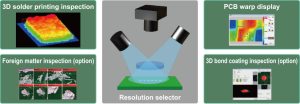

- Equipment: 3D Solder Paste Inspection (SPI) Machine.

- Function: Uses structured light and triangulation to measure the volume, height, and area of every paste deposit. It provides a real-time, quantitative analysis of printing quality.

- Quality Reliance: High-speed, high-accuracy 3D measurement is non-negotiable. Quality SPI provides crucial feedback data to the printer, enabling closed-loop control and preventing a mass of defective boards from moving down the line.

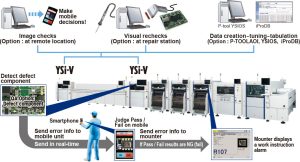

- High-Speed Component Placement

The core of the SMT line where components are mounted.

- Equipment: High-Speed Pick-and-Place (PnP) Machines (often two or more in series).

- Function: Accurately picks components from feeders and places them onto the pasted PCB. The first machine often handles high-volume, small passives (chips), while the second (sometimes called the “Flexible Placer”) handles larger, complex ICs and connectors.

- Quality Reliance: Placement accuracy (down to 25μm for fine-pitch BGAs), nozzle/feeder reliability, and vision system speed determine throughput and placement yield. A high-quality PnP machine minimizes placement errors (misalignment, missing components, polarity issues).

- Reflow Soldering

The process where the electrical and mechanical bond is formed.

- Equipment: Forced Air Convection Reflow Oven (often 8 to 12 heating zones plus a cooling zone).

- Function: Executes the precise thermal profile (preheat, soak, reflow, cool) required to activate the flux, melt the solder paste, and form the final metallurgical joint.

- Quality Reliance: Zone temperature uniformity, thermal profile repeatability, and reliable forced convection (often under a Nitrogen atmosphere to reduce oxidation/dross) are vital. A superior oven ensures consistent Time Above Liquidus (TAL) across the entire board, preventing defects like tombstoning or cold joints.

- Automated Optical Inspection (AOI)

The final electronic eye that verifies assembly quality.

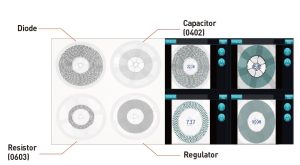

- Equipment: 3D Automated Optical Inspection (AOI) Machine.

- Function: Inspects the completed assembly post-reflow. Uses 3D triangulation and 2D color imaging to detect defects such as component presence/absence, polarity, misalignment, and critical solder joint issues (shorts, insufficient solder, lifted leads).

Quality Reliance: High-resolution 3D imaging is superior for inspecting the complex geometry of solder fillets and verifying coplanarity, which a 2D system cannot reliably measure. A high-quality AOI system minimizes both false calls (unnecessary rework) and escapes (undetected defects).

- Auxiliary & Support Equipment

These components ensure efficiency and traceability:

- Conveyors: Automate material flow.

- Loaders/Unloaders: Manage PCB magazines at the start and end of the line.

- Barcode Readers: Critical for Product Traceability and verifying the correct program is run.

- Component Counter: (Often an X-Ray counter) to maintain accurate inventory.

The Indispensable Link Between Machine Quality and Product Quality

In PCBA manufacturing, the quality of the equipment is not just an operational cost; it is the primary determinant of final product reliability and operational throughput.

- Repeatability and Accuracy: Lower-quality machines suffer from poor long-term repeatability. A premium PnP machine maintains its accuracy tolerance over millions of cycles, ensuring consistently centered and level placement. Cheaper machines drift, introducing random placement errors that necessitate higher inspection and rework rates. The failure of a machine to maintain its precision (e.g., poor printer alignment) creates systematic defects, meaning a high percentage of all boards produced during that shift may be compromised.

- Process Control: High-end equipment integrates sophisticated sensors and control loops (e.g., in ovens and printers). A quality SPI machine enables the crucial closed-loop feedback that corrects printing errors before the component is committed. Without this, a manufacturer is simply inspecting defects rather than preventing them.

- Total Cost of Ownership (TCO): While the initial investment in high-quality equipment is significant, the long-term TCO is lower. High-quality lines minimize costly rework, reduce material waste (from scrapped PCBs), and maximize Overall Equipment Effectiveness (OEE) by reducing unexpected downtime and improving yield.

As an industry leader in PCBA manufacturing, P&C focuses on investing in high-end, well-maintained SMT equipment as the most effective strategy to ensure and maintain product quality.

Source: PCES